Hydraulic vs. Pneumatic Stroke Cylinders: Which is Best for Your Needs?

Knowing the differences between a hydraulic or pneumatic cylinder will help you make the right choice. Cylinders are used to help push and pull heavy things.

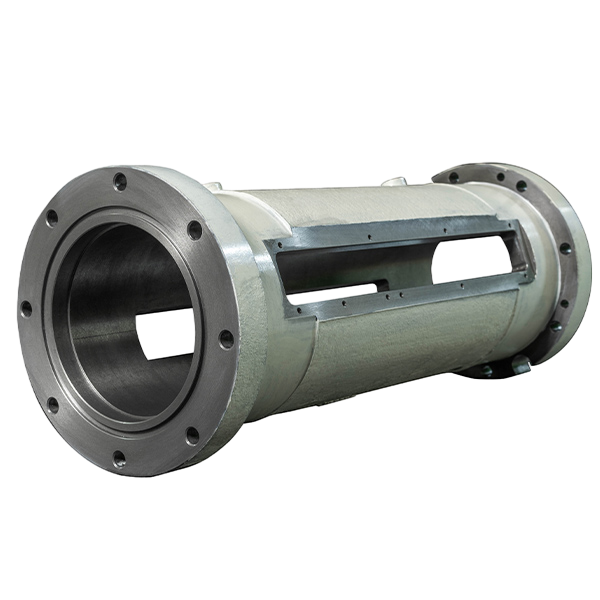

They are used to push and pull things, but they do not use the same technology. A split bearing housing pushes or pulls things using oil that is pushed by a pump. In contrast, a pneumatic cylinder uses compressed air to push a piston inside it. These can offer different advantages and disadvantages depending on your personal preferences.

If you are looking to comparing which might be best for you there are a few things to consider. Machines such as construction and other big machines use split housing bearing due to how strong they can be to lift heavy loads. However, they are much slower and costlier to run than pneumatic cylinders.

Pneumatic cylinders are commonly used in smaller applications such as block bearing housing and robotics due to how less powerful but faster, and cheaper to use they are. When considering which is best for your needs, there are a few things to consider. If you plan to lift large or heavy objects and have the budget required to run them, a hydraulic cylinder may be the perfect thing for you.

However, if you need something that works quickly and has lower costs, a pneumatic cylinder may be the right choice. There are other information to consider for both uses, such as which is best to cover for your use. No matter which cylinder you choose, you will be able to find many types that suit your preferences.

Comments

Post a Comment